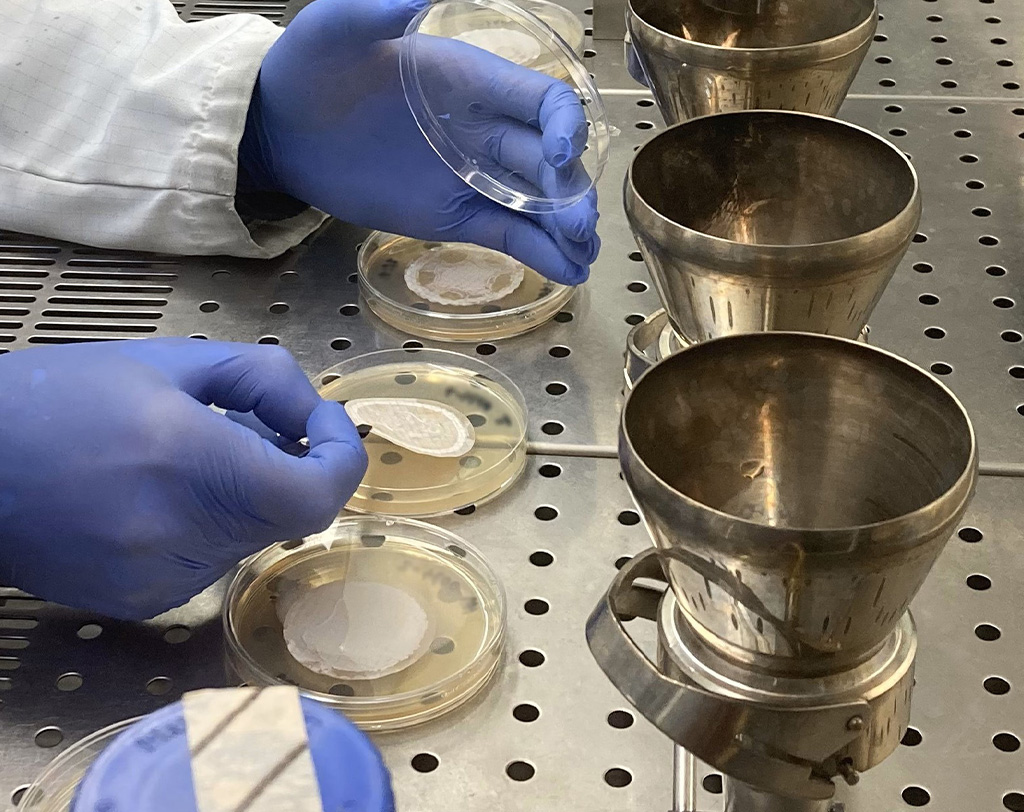

I.M.U. GmbH is an independent chemical laboratory based in Klosterneuburg, accredited according to EN ISO 17025, SCC-certified, and operating an accredited inspection body under EN ISO 17020. With over 30 years of experience, the specialized laboratory's core competence lies in the analysis of fuels, combustibles, and alternative fuels.

IMU is a reliable partner as an independent testing facility for industry and commerce. In addition to testing standard parameters according to the relevant fuel and combustible norms, the laboratory also develops specialized procedures for new, innovative products produced through the pyrolysis of fossil and biogenic waste or other biogenic raw materials.

Since the beginning of 2024, the laboratory has been part of the AGROLAB GROUP.

Institut für Mineralölprodukte und Umweltanalytik GmbH

Aufeldgasse 37 - 39

3400 Klosterneuburg

Austria

Tel. +43 664-88907435

This email address is being protected from spambots. You need JavaScript enabled to view it.

Directions

Opening hours:

Monday - Thursday: 8:00 - 16:00

Friday: 08:00 - 13:00

Contact

Contact

Contact

Contact Career

Career